Completions Solutions

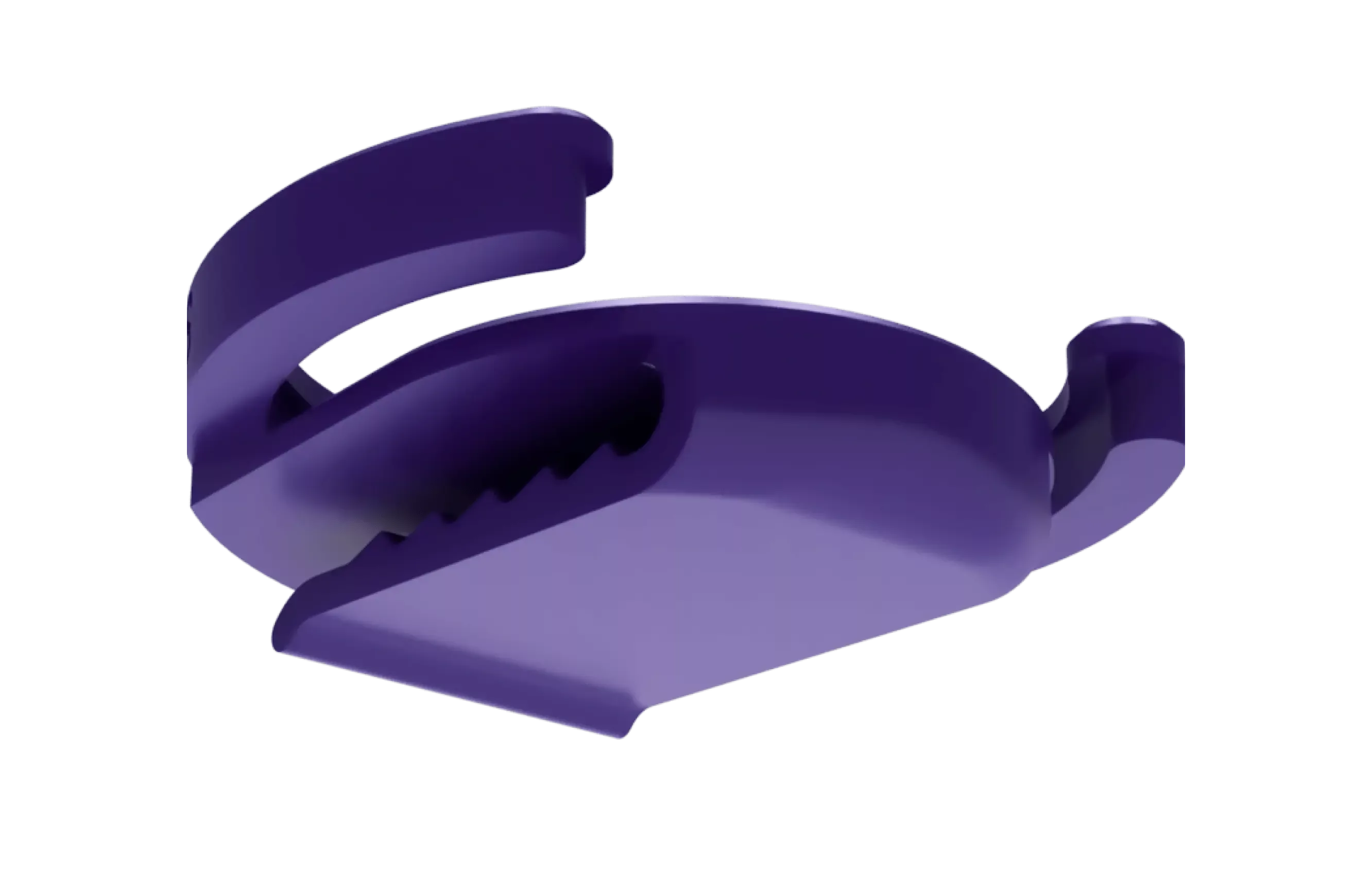

V-TOOL

The Industry's Standard Measurement Tool for Frac Plug Cuttings.

The need for continuous improvement in completion composite plugs and milling technologies have risen dramatically over the past 10 years. As E&P companies increase the operating standards towards greater hydraulic frac capacity and increasing setting depths, challenges such as pre-setting during installation, longer run-in times, and plug cuttings removal present a greater desire for more data and the knowledge of how to perform... better.

After a composite plug has been deployed and frac'd against it must face its last challenge; the drillout operation. An E&P company's objective is to remove the plugs, often more than 100 per well, as efficiently and quickly as possible. The plugs are milled by a chosen method of either a roller cone or fixed cutter drill drill bit, or a mill forged by welded crushed carbide. Regardless of the method, the intent is to mill the plug into as small of cuttings as possible and flow this debris out of the well via drilling fluid. These materials are light in weight, which facilitate faster pump-down times and result in finer mill-out cuttings for manageable debris.

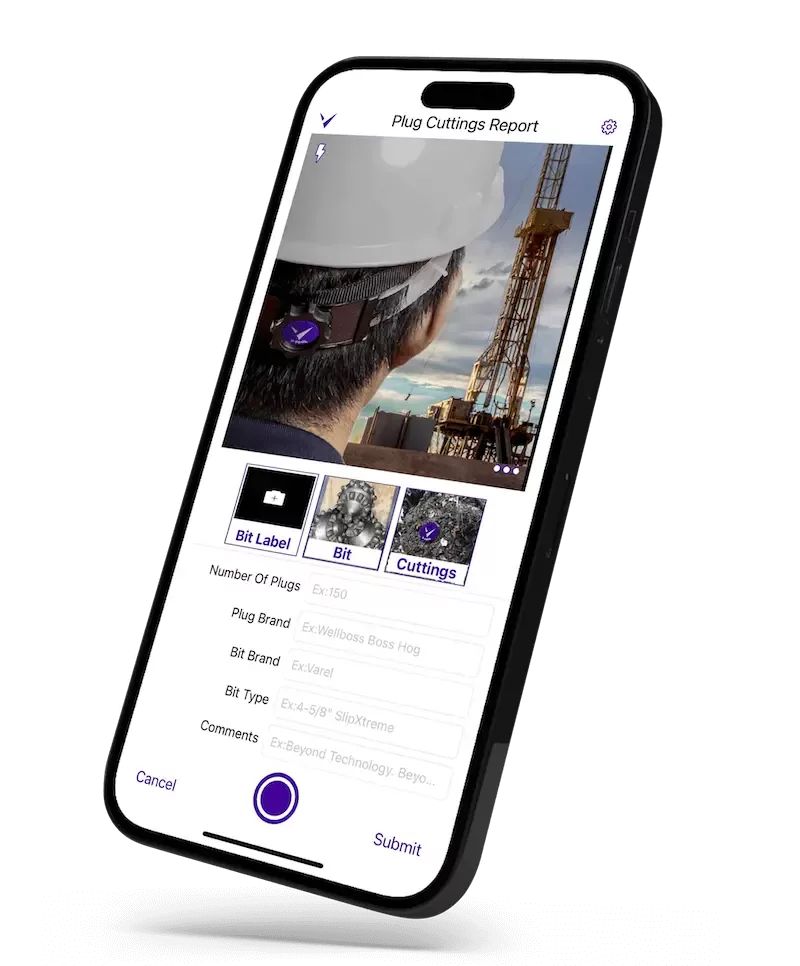

Product and service providers that specialize in the performance of the drillout operation gather data from plug cuttings samples to determine the effectiveness of the milling as well as the composite plug itself. These companies will use this performance data to undergo testing, quality analysis and iterative improvements to the product and processes. However, there are no uniform standards towards how to effectively measure composite plug debris. In the field, items such as monetary coins, rulers or "snuff" cans are used to illustrate relative sizing in photos. Though practical, there is no basis for normalizing this data. It is time for a set standard.

The V-TOOL by Varel Energy Solutions is designed to offer a common platform for capturing operational data and practical insight on milling technology and frac plug performance. This is a tool for the industry, but for Varel Energy Solutions, this integrates directly into our 360° Customer Workflow whereby we use this information to make product improvements, validate predictive performance and gain valuable customer insight.

The V-TOOL will set the stage for the next generation of plug and perf completions best practices, which will drive further enhancements in customer value, product performance, reliability and repeatability.