NEW

Drilling Solutions

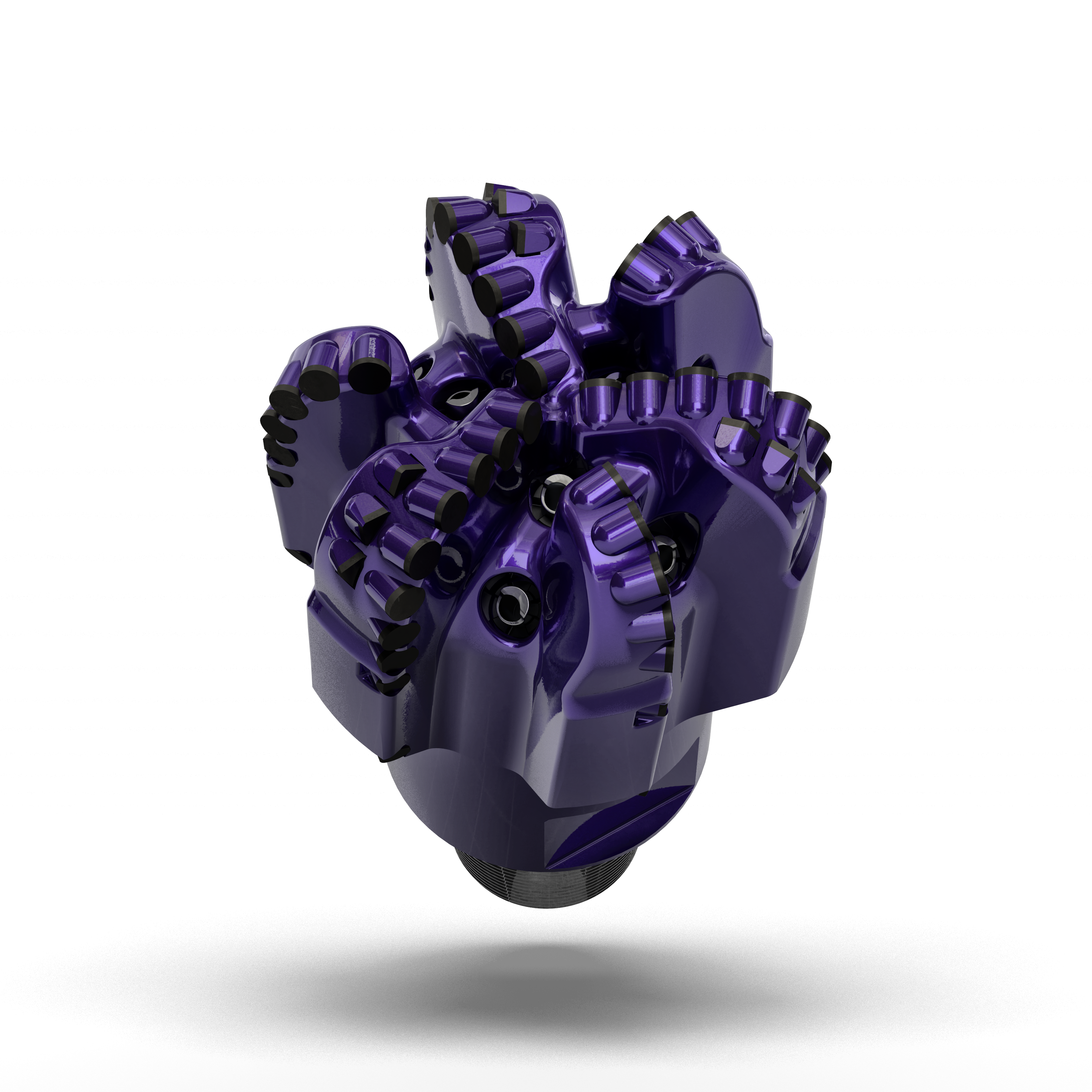

A-FORCE™ PDC

Introducing Varel's NEW, A-FORCE™ "Air PDC" Drill Bit series; our Air PDC products are designed specifically for drilling on air or mist in an underbalanced environment. Our proprietary technology caters to operators and service companies' expectation for speed, durability, steerability and increased bit longevity. A-FORCE Air PDC's effectively drill vertical, tangent, and curve sections without the loss of performance in transitioning to various sections of the wellbore. The A-FORCE design introduces a unique airflow control feature, effectively cooling the bit and lifts cuttings out of the wellbore without the conventional use of liquids. The result for operators is faster drilling and improved ROP, while helping eliminate lost circulation problems.

Application

- Bit Design, Features, and Cutters specific to drilling on AIR

- VION PDC "Tangent" Drill Bit Series developed specifically for AIR drilling applications where drilling through transitions requires enhanced durability and control

- Various designs and sizes are capable of building and holding +/- 60°

- AIR PDC features improve hole cleaning and help to remove cuttings immediately

- For soft to hard formations where high ROP is expected

- Sizes for AIR PDC Drilling range from: 6-1/8" to 24"

Air PDC Drill Bit

For specs, applications, availability, costs and shipping please contact your local Varel Rep today.

Call: 1(281) 272-6000

Email: info@varel.com

Features/Benefits

• VENOM™ Cutter technology utilizes the right PDC cutter solving various challenges while drilling on air

• Hydraulic optimization – “HYDRA”, VES’s hydraulicallyoptimized features include curved nozzles, twister nozzles, webbed blades and CFD optimized nozzle placement

• Airflow control cooling the drill bit while effectively lifting cuttings from the wellbore

• Greater ROP potential as compared to traditional air-drilling bit designs, reducing the likelihood of performance limitations

• Greater dull grade results in less damage to the bit and cutter substrates while improving borehole quality over traditional drill bit designs